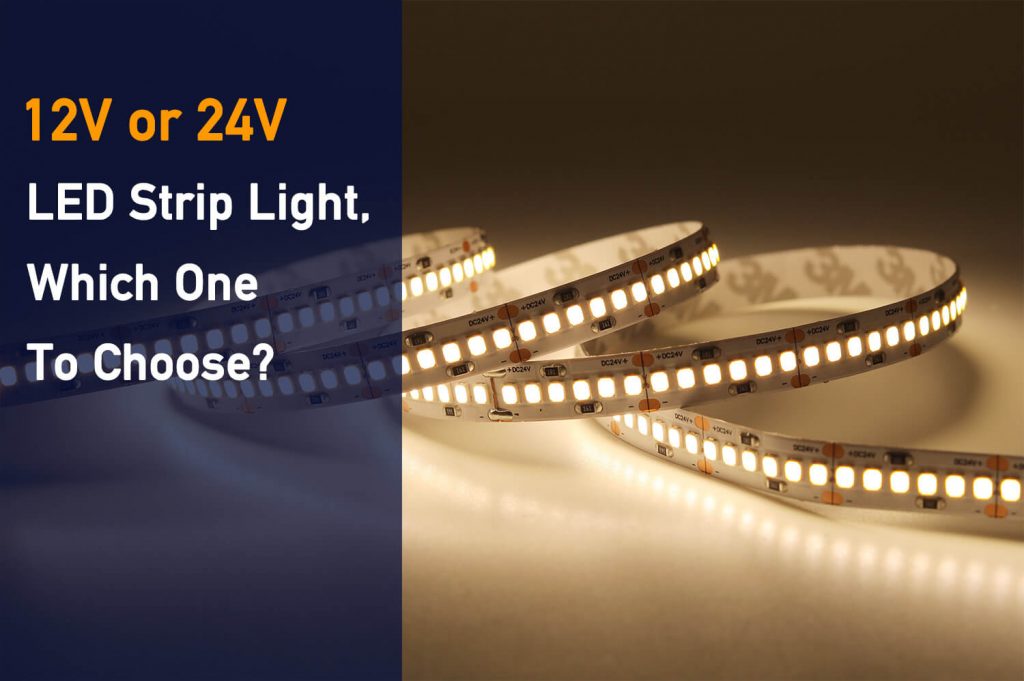

LED strip lights are available in both 12V DC and 24V DC voltage input. There are a few things to consider when choosing them, such as brightness, run-length, and cut interval. Generally, 12V strips have shorter cut intervals, 24V strips can have a longer running length before voltage drop occurs.

Which one should you get for your project, 12V or 24V? If you want to know their fundamental differences, this article is for you. We’ll go through each of their distinctions to aid you in your buying decision.

1. Electrical Circuit Design

Most single SMD LEDs are 3-volt devices. To light them up, you’ll need to apply a three-volt differential between their positive and negative ends.

Strip lights have a string of many LEDs lined up one after another. By structuring the LEDs into a particular series vs. parallel combination, you need to match the LED system to a power supply voltage.

In contrast, a 12V LED system is configured at 3 LEDs in series per string, it sums up into an LED voltage of only 9V(3V*3pcs), about 75% of the 12V input. This means that roughly 25% of voltage energy is wasted.

A 24V LED system generally makes 6 LED lamp beads in a cutting length, but its overhead voltage can also take 7 LEDs in a series to pursue a higher light efficacy. When there are 6 LED lamp beads in each group, the total voltage is 18V (3V*6pcs), which is about 75% of the 24V input; while when each group has 7 SMD LEDs, the total voltage is 21V (3V7%). This is about 88% of the 24V input, and only about 12% of the voltage energy is wasted as heat.

- 2835 140LEDs/m 24V High Efficacy LED Strip Light

In a nutshell, 24V is better suited for LEDs than 12V DC. You can reduce fundamental electrical design flaws by over 50% when you use 24V systems.

2. Current Flow

At the same power level, the 12V LED system will draw twice the amount of current than a 24V.

As an example, if 48W (power) is your target output, the 12V system will need four amps since 48W = 12V x 4A (power = voltage x current). While 24V system needs only 2A to reach 48W power.

The current decides the size of copper conductors, they are necessary to transfer power safely. If an enormous amount of current goes through a narrow copper PCB, the resistance will grow. Too much resistance can lead to heat and voltage drops. 24V systems are more efficient since they draw half of the current.

3. Max Running Length (Voltage Drop)

All LED strip lights will experience a voltage drop. 12V LED systems draw larger currents and accumulate more considerable resistance, this resistance will lead to voltage drops. Voltage drops in the 12V strip are higher than 24V.

We tested the voltage drop for 12V LED tape and 24V LED tape separately. As you see the result in below pictures, the 12V LED tape light gets a 15% voltage drop while the 24V LED tape has only 5.5% voltage drop.

- Voltage drop test for 12V LED strip

- Voltage drop test for 24V LED strip

Therefore, both 12V and 24V strips have their maximum run length. When it comes to maximum running length, 24V LED strip lights typically run longer than 12V LEDs. For example, The 24V 2835 120LED 9.6W led strip, you can run it 7 meters long by power from one side. If the voltage is 12V, we don’t recommend running the length over 5 meters.

4. Luminous Efficiency

Both 12V and 24V LED strip lights are low-voltage, energy-efficient devices. When it comes to luminous efficiency, the 24V strip will be a little higher than 12V.

Just like any other electrical circuit, the LED strip’s circuits will produce resistance and generate heat. If both strip lights have the same power, the 12V one will draw a bigger current and generate more heat on the PCB. More wasted energy causes a lower luminous efficiency.

5. Brightness

Under the same power, the brightness of the 24V strip will be slightly higher than 12V, but it is difficult to see the difference with the naked eye.

If you need only 510-1150 lm/m for mood or accent lighting, then you can select either a 12V or 24V light strip. But when it comes to industrial lighting such as signage, linear lighting. You’d better use a 24V strip.

6. Cut Interval

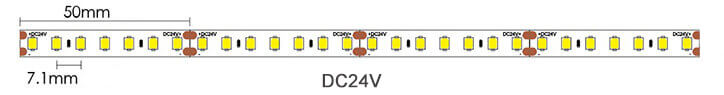

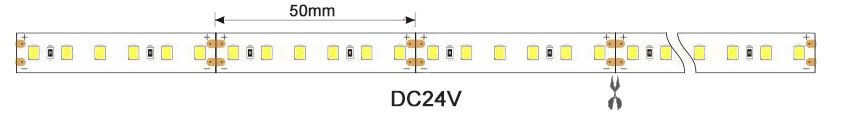

Generally, the 24V light strip is cut off with 6 or 7 LEDs, the 12V strip is cuttable at 3 LEDs.

- 2835 120LEDs/m 12V LED Strip Light

- 2835 120LEDs/m 24V LED Strip Light

At the same density, the cuttable length for a 12V LED strip light is only half of 24V’s. For example, the strip 2835 120 LEDs per meter, will have cutting intervals of 50mm on 24V and 25mm on 12V.

If your project needs lighting at tight corners, 12V strips can provide accurate lengths since they’re cuttable at a shorter length.

7. Application Range

Most electrical systems operate on a 12-volt direct current power supply. Because of the general usage of 12 volts. For lighting projects in hotels, Bars, restaurants etc. 24V is more common to use.

- 12 V

12Vs are suitable for smaller installations, such as in cars, boats, and other applications that use 12V power sources. Remember that 12Vs have smaller cuttable lengths, it’s more flexible in tight spaces.

- 24 V

If your project requires longer runs of strip lights or high lumen output, 24Vs may be more suitable. 24Vs are perfect for surfaces where you don’t have to worry about tight spaces.

8. Power Supply

Both 12V and 24V designs need a power supply unit for them to operate. Whichever format you choose, both have an assortment of power supply options in the market. You can quickly get them anywhere, particularly online.

9. Frequently Asked Questions

Are 12V And 24V Strip Lights Compatible?

If the light project of 12v LED tape has 24V LED connected, the 12V LED stripe does not light up. If you happen to use a RGB LED stripe, you may glow faintly red. On the flip side is the 12V strip connected to 24V LED strip light which with 24V power supply, it is even more dangerous. Within seconds of time being connected to the 24V power unit, the 12V strip becomes overheated. If you don't turn off the power in time, the 12V LED tape will get smoking hot, the LED strip light will be damaged or even catch fire.

Is 12V Strip Safer than 24V?

In theory the 12V will be safer, but there’s very little difference since both are of relatively low voltage rating. However, as mentioned earlier for the voltage drop and efficiency. the lower voltage will cause more losses, you will find more voltage drops in a 12-volt system.

Will a 24V LED Strip Work on 12V?

You won’t be able to connect a 24V strip to a 12V power source without installing a transformer or voltage booster. 24V strips have a 6-LED (or above) series per string. there is no way to "split" this to match a 12V power source.

Will a 12V LED Strip Work on 24V?

If you’re wondering if you can go the other way around - connect a 12V strip to a 24V source, you also won’t get very far. The 24V power will cause the led strip to burn out due to over-voltage.

Which LED Strip is Better - 12V or 24V?

Which of the two designs is better depends on your application. By now you should have a good understanding of their advantages and disadvantages. If cut length isn’t a concern, 24Vs are ideal since you can spread them further. If your project requires shorter increments due to spatial issues, 12Vs should be your go-to.

The Final Words

12V and 24V LED strips have only slight differences. You can use both in many different applications and functions. Before making a buy, it’s better to understand what you want to get out of your lighting project. Having a good lighting plan can help you in making the right decision.

Myledy provides top-of-the-line, affordable LED strip light products. For over 17 years, we have provided premium LED products for any lighting project, big or small.

We know LEDs like the back of our hands. As a leading manufacturer, we commit to 100% customer satisfaction.If you want high-quality LED lighting solutions, get in touch with us today!