12V and 24V DC is the main input voltage for led strip lights, they are safe and easy to work with. However, We often encounter this phenomenon: the strip is bright at one end and looks dimmer at the other end, why?

Actually, this is very normal in low voltage lighting systems, because of the voltage drop. In this article we’ll talk about:

Let’s get started.

1. What’s a Voltage Drop?

The voltage drop usually occurs when the current passes through the conductor. the greater the resistance in the circuit, the higher the voltage drop.

In the DC circuit of the led strip, the voltage will gradually drop as it passes through the wire and the strip light itself. So with the extension of the wire or strip, it will lead to one side of your strip lights being brighter than the other side.

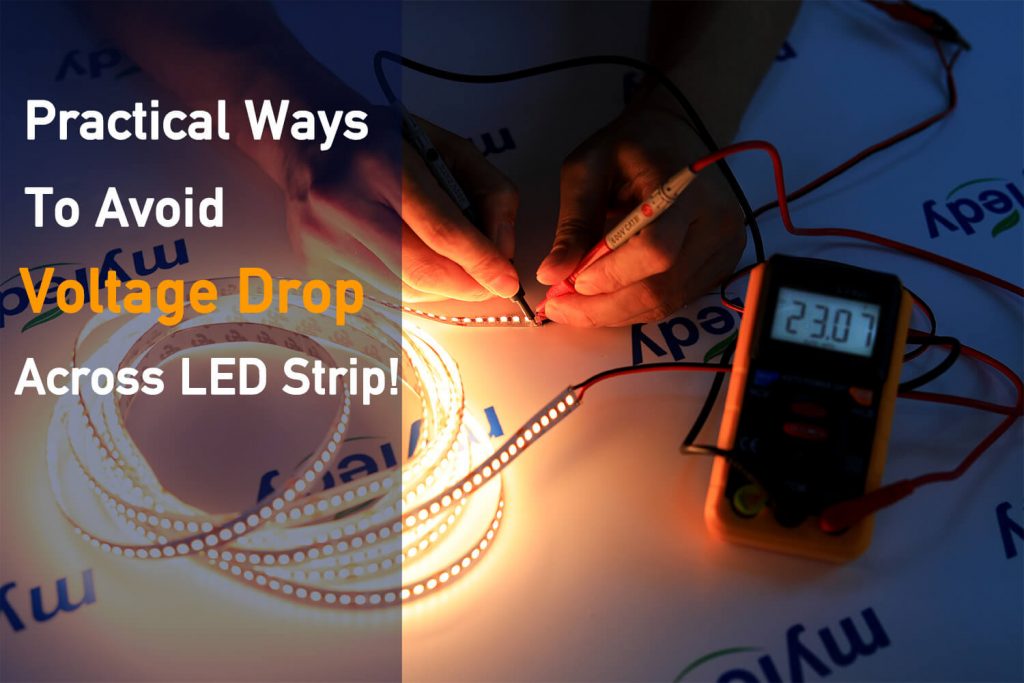

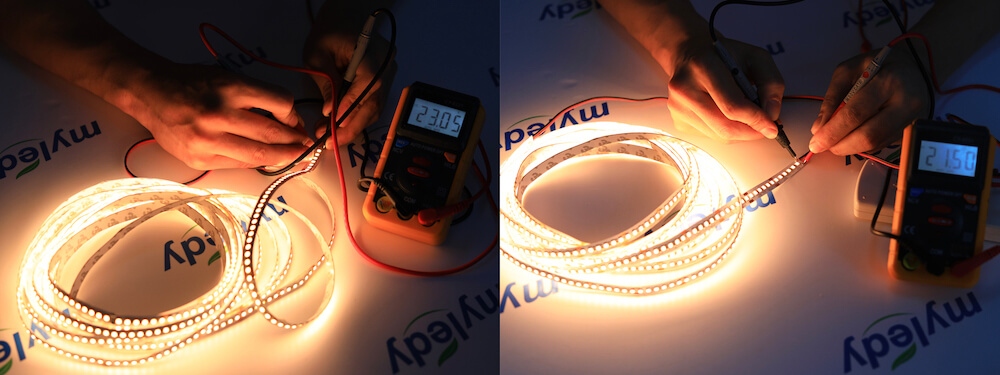

We tested the led strip 2835L-120led/m-9w-24v, as shown in the figure above, the power voltage is 23.39V, and the tail voltage has dropped to 22.12V, which will cause the problem of inconsistent brightness at the total of the light strip.

2. How Does a Voltage Drop Happen?

The degree of voltage drops in LED strips can be determined by the main factors: voltage input (12V or 24V), wire gauge, wire run length, and total strip lighting load (Watts & amps).

Voltage input (12V or 24V)

The higher the voltage, the smaller the voltage drop.12V LED strips will lose voltage faster than 24V strip lights, so if you are running a led strip over 10 meters, we would recommend going with 24V strips.

For example, The 24V 2835 120LED 9.6W strip, which is five meters long, measured the beginning voltage at 23.39V and the end voltage at 22.12V – a difference of 1.27V, or 5.4%.

But on a 12V DC 2835 120LED 9.6W strip strip, measured the beginning voltage at 11.82V and the end voltage at 10.03V – a difference of 1.79V, or 15.1% – an bigger voltage drop than 24V – so the LED chips at the end of the strip would be noticeably dimmer than the ones at the beginning.

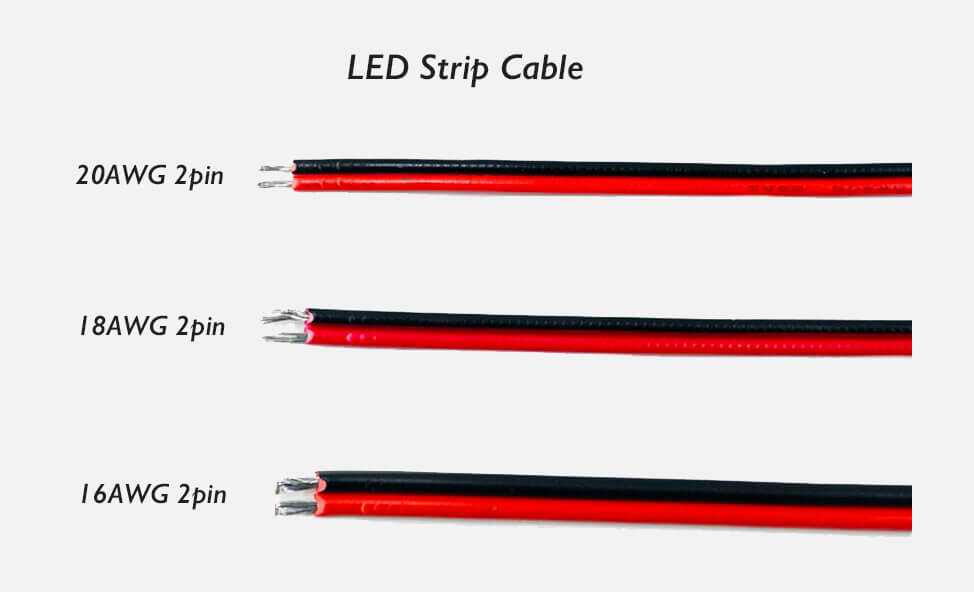

Wire gauge

The larger the wire size, the smaller the voltage drop. For example, when connecting a 10w 24v led strip, we can use a 26-meter 20AWG wire, to deliver current with less than 3% voltage drop. But if we change to 16AWG wire, the distance can reach 65 meters.

Wire length

For wires of the same size, the longer the wire, the greater the voltage drop. When the wire becomes very long, the voltage drop becomes very obvious. If the distance between the strip and the power supply is too long, the running efficiency of the led strip will be affected and become dim.

Amount of current

The amount of current being carried can affect voltage drop levels. Voltage drop increases on a wire with an increase in the current flowing through the wire. Current carrying capacity is the same as ampacity. In the picture below:

Our 24V DC 2835 180LED 14.4W strips, which are five meters long, we measured the beginning voltage at 23.05V and the end voltage at 21.5V – a difference of 1.55V, amount to 6.7% of the original voltage – more than 24V DC 2835 120LED 5m strip.

3. How to Avoid Voltage Drop?

Although the voltage drop is a problem with LED strips, we can avoid by following these tips:

Parallel Connections

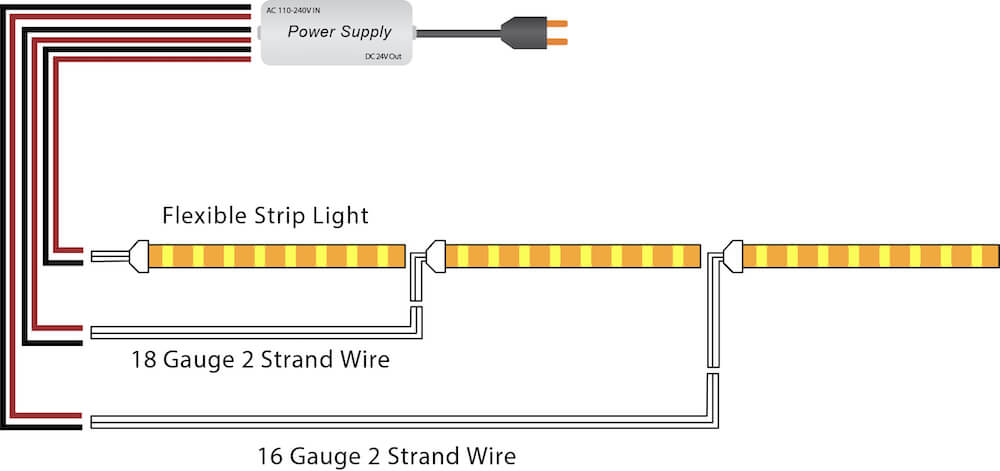

If you wish to install a continuous run of over 20 meter of 2835 120led 24V 9.6W, use parallel connection. Check below picture:

One of the best ways to avoid voltage drop is by running multiple parallel connections. This is beneficial when you want to install a continuous run of LED strips. For example, you have 30 meter of LED strip lights rated 24V at 9w/m. To avoid voltage drop, divide the 30 meters of LED strip lights into shorter units.

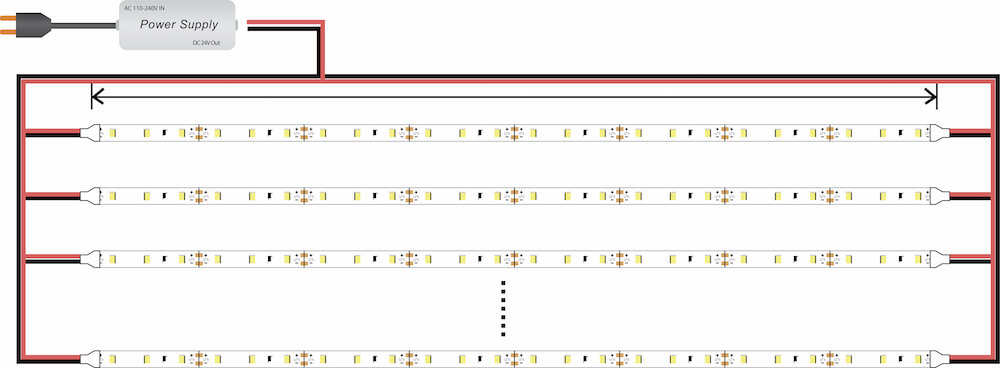

- A: Divide it into 6 units of 5 meter. Power them one side:

- B: Divide it into 3 units of 10 meters. Power from both sides:

- Please note, for different power of led strip lights, the recommended max running length could be different, take our 2835L strip series for example:

| Item No. | Power | Max length (Power from one side) | Max length (Power from both sides) |

| LD-2835L-24-60S08-05P0-W | 4.8w/m | 10m(32ft) | 20m(64ft) |

| LD-2835L-24-120S08-09P0-W | 9.6w/m | 7m(23ft) | 14m(46ft) |

| LD-2835L-24-180S10-14P0-W | 14.4w/m | 5m(16ft) | 10m(32ft) |

| LD-2835L-24-240S10-19P0-W | 19.2w/m | 3m(10ft) | 6m(20ft) |

Use 24 Volt Supplies

If you’re planning to install LED strips of more than 10 meter, it is best to go with 24 Volts strips. In 12V strips, the voltage drops are much faster, so they don’t support longer LED strips.

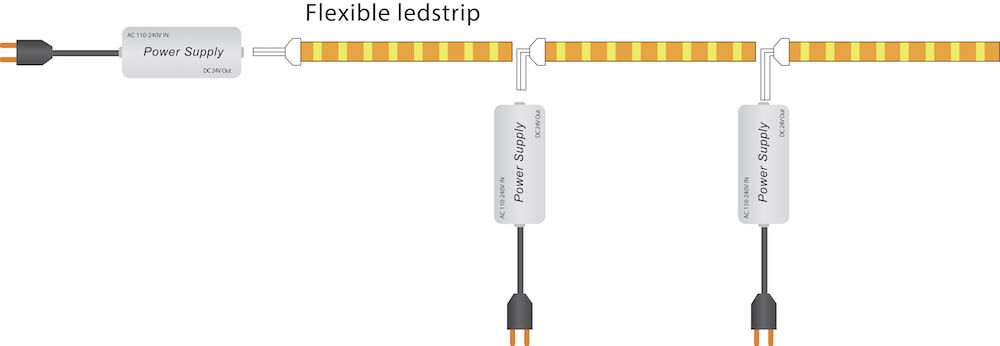

Multiple Power Supplies

Using multiple power supplies instead of a single unit is a great idea to get better brightness. It requires strategic planning so that you don’t end up too far from the power source.

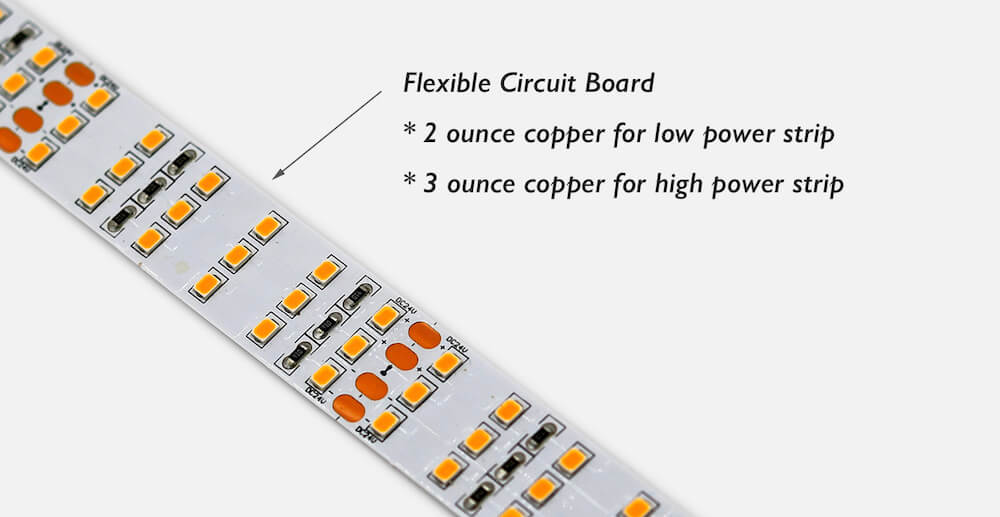

Use an Led Strip With Thick Copper PCB

Copper is the most popular material used in electrical wiring. This is because it conducts electricity much better. The thickness of copper is usually rated in ounces. The thicker the copper wire, the more current can flow through. We recommend using 2 ounces, or 3 ounces for higher power LED strips to avoid voltage drop.

The thicker the copper wire, the less the internal resistance. As such, the copper wire will carry power more efficiently. In addition, It’s more conducive to heat dissipation.

Identify Correct Wire Gauge

If you have long cables, always use thick copper cables to minimize voltage losses. While deciding the right cable thickness, we can use a gauge chart. The gauge chart helps in selecting the right thickness for the LED strip’s power consumption. To deliver current with less than 3% voltage drop

Here are some simple steps to determine the right wire gauge.

Step 1. Calculate the Wattage

First, find out the total wattage of your LED strip. Usually, the wattage is mentioned on the strip label. So, you can multiply that with the total length to find the rated power.

Example: LD-2835L-24-120S08-09P0-W consumes 9.6 watts per meter. If you are using 10 meter. (10 x 9.6) = 96 watts

Step 2. Find the Distance Between Lights and Driver

Now, you need to measure the distance between your driver and the LED strips. It directly affects the wire gauge.

Step 3. Picking the Right Gauge

Now that you know the requirements, you can pick the right gauge from the chart. It’s best to take professional help while selecting the correct gauge. It ensures safety and prevents possible problems in the future.

While mapping your readings, always round up the values to a higher closest rating. It ensures better protection and efficiency of your LED strips.

12V Voltage Drop & Wire Length Distance Chart

| Wire Gauge | 10W/0.83A | 20W/1.7A | 30W/2.5A | 40W/3.3A | 50W/2.1A | 60W/4.2A |

| 20AWG | 5.5m(18ft) | 2.7m(9ft) | 1.8m(6ft) | 1.5m(5ft) | 1.2m(4ft) | 0.9m(3ft) |

| 18AWG | 10.3m(34ft) | 5.1m(17ft) | 3.3m(11ft) | 2.4m(8ft) | 1.8m(6ft) | 1.5m(5ft) |

| 16AWG | 16.4m(54ft) | 8.2m(27ft) | 5.4m(18ft) | 3.9(13ft) | 3m(10ft) | 2.7m(9ft) |

| 14AWG | 26m(86ft) | 13m(43ft) | 8.8m(29ft) | 6.4m(21ft) | 5.1m(17ft) | 4.2m(14ft) |

| 12AWG | 40m(134ft) | 20m(68ft) | 13m(45ft) | 10m(34ft) | 8m(27ft) | 6.7m(22ft) |

| 10AWG | 60m(199ft) | 30m(99ft) | 20m(66ft) | 15m(49ft) | 12m(39ft) | 10m(33ft) |

24V Voltage Drop & Wire Length Distance Chart

| Wire Gauge | 10W/0.42A | 30W/1.3A | 50W/2.1A | 70W/2.9A | 90W/3.75A | 100W/4.2A |

| 20AWG | 25.9m(85ft) | 8.2m(27ft) | 5.1m(17ft) | 3.6m(12ft) | 2.7m(9ft) | 2.4m(8ft) |

| 18AWG | 40.8m(134ft) | 13.7m(45ft) | 8.2m(27ft) | 5.8m(19ft) | 4.5m(15ft) | 4.2m(14ft) |

| 16AWG | 65.5m(215ft) | 21.9m(72ft) | 13.1m(43ft) | 9.4m(31ft) | 7.3m(24ft) | 6.7m(22ft) |

| 14AWG | 105m(345ft) | 35m(115ft) | 21m(69ft) | 15m(49ft) | 12m(39ft) | 11m(36ft) |

| 12AWG | 164m(539ft) | 55m(181ft) | 33m(108ft) | 23(77ft) | 18m(61ft) | 17m(56ft) |

| 10AWG | 238m(784ft) | 80m(263ft) | 48m(158ft) | 34m(112ft) | 29(97ft) | 25m(82ft) |

The last words

Remember, always consult a professional electrician before doing any electrical work. The electrical system in your home is a complex network of wiring. To prevent damage, and make the process less painful, find an experienced electrician.

Can I install a continuous run of over 20 meter strip by series connection? Sure, you can use constant current LED strip. Click here to learn more.