specifications:

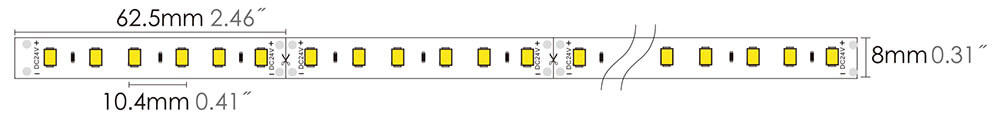

- Item No. : LD-2835L-24-60S08

- Dimension(24V)

- Technical Details

Power 4.8 w/m Light efficacy 100 lm/w (+/-10%) Luminous flux 456~513 lm/m PCB width 8 mm Voltage DC 12V / 24V Cutting interval 50 mm / 100mm IP lever

- Item No. : LD-2835L-24-96S10

- Dimension(24V)

- Technical Details

Power 7.7 w/m Light efficacy 100 lm/w (+/-10%) Luminous flux 730~821 lm/m PCB width 10 mm Voltage DC 12V / 24V Cutting interval 31.3 mm / 62.5mm IP lever

- Item No. : LD-2835L-24-120S08

- Dimension(24V)

- Technical Details

Power 9.6 w/m Light efficacy 100 lm/w (+/-10%) Luminous flux 912~1026 lm/m PCB width 8 mm Voltage DC 12V / 24V Cutting interval 25 mm / 50mm IP lever

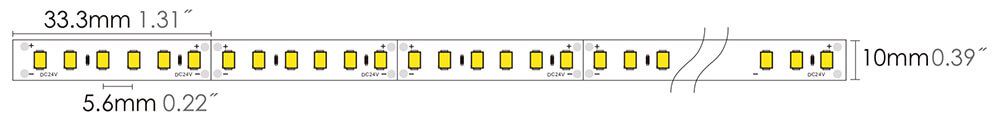

- Item No. : LD-2835L-24-180S10

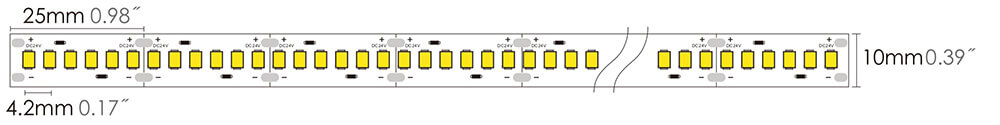

- Dimension(24V)

- Technical Details

Power 14.4 w/m Light efficacy 100 lm/w (+/-10%) Luminous flux 1368~1539 lm/m PCB width 10 mm Voltage DC 12V / 24V Cutting interval 16.7 mm / 33.3mm IP lever

- Item No. : LD-2835L-24-240S10

- Dimension

- Technical Details

Power 19.2 w/m Light efficacy 100 lm/w (+/-10%) Luminous flux 1824~2052 lm/m PCB width 10 mm Voltage DC 24V Cutting interval 25 mm IP lever

- Item No. : LD-2835LG-24-140S08

- Dimension

- Technical Details

Power 9.6 w/m Light efficacy 120 lm/w (+/-10%) Luminous flux 1100-1180 lm/m PCB width 8 mm Voltage DC 24V Cutting interval 50 mm IP lever

Introduction of 2835L SMD LED:

As Myledy’s star product, 2835L low Power LED Strip is widely welcomed by main clients. 20 mA current each 2835 LED. 60 ~ 240 LEDs / M densities and and 450 ~ 1180 LM/M option to satisfy various requirements. >90 or even higher CRI, 2000K ~ 7000K wide CCT Excellent heat dissipation and lighting performance made it popular in the market and quickly replaced 3528 and 3014 SMD.

Key Features for Your Selection:

- >90 CRI(Color Rendering Index)

- 2000K~7000K Widely CCT range

- Up to 2 Step Color Consistency

- Fully Dimmable

- Perfect Heat-dissipation to ensure 50000hours Lifespan.

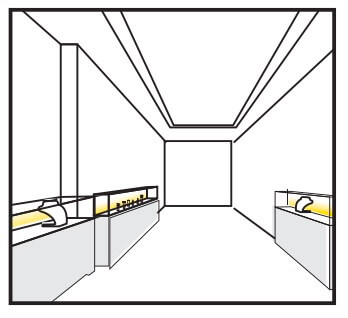

Application & Wide Use

Based on HIGH CRI ( >90) and lower lumen, Myledy 2835L low power LED light strips are more widely installed in variety of indoor applications including:

- TV backlighting

- Bedroom lighting

- Display / jewelry case lighting

- Bar and restaurant accent lighting

- Above cabinet lighting

- Under counter lighting

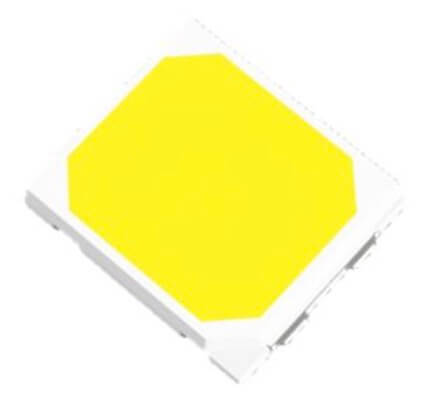

Why we use 2835 instead of 3528 & 3014?

| LED SMD | Picture | SMD Size | Luminous Area | Lateral Luminescence | Heat Dissipation Form | Heat Dissipation Effect | Luminous Angle |

| 3528 SMD |  | 35*28*1.9 mm | 4.5㎡ | Normal | No | Poor | 95° |

| 3014 SMD |  | 30*14*0.8 mm | 3.64㎡ | Weak | With heat sink | Normal | 90° |

| 2835 SMD |  | 28*35*0.8 mm | 9.18㎡ | Strong | With heat sink | Excellent | 120° |

The Outstanding Features of 2835 SMD LED:

- the chip uses high-power back aluminizing process, heat dissipation is more direct.

- The heat of the chip is derived directly from the bottom of the bracket, which has a larger heat dissipation area and better heat dissipation performance than 3014.

- The luminous surface is rectangular, with large luminous area, large luminous angle and uniform luminous area relative to 3014 and 3528. The luminous area is 2.3times of 3014 and 2.1times of 3528.

- 2835 is an upgraded new light source, which is widely used, overcomes the disadvantage of small side luminous angle of 3014, and effectively solves the phenomenon of point light source in 3528 lighting application.

- According to the product model and customer heat dissipation conditions, a variety of currents of 20-50 Ma can be used.

- To increase the light transmittance by 10%, 85-95% light transmission cover can be used, especially on LED fluorescent lamps.

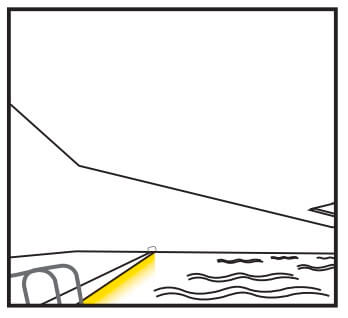

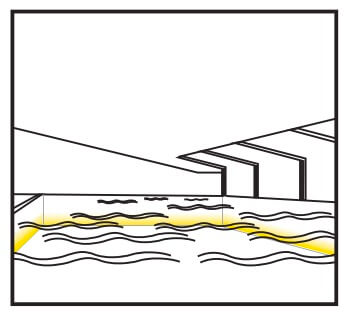

Myledy IP Grade Introduction:

IP is an acronym “Ingress Protection”, a measurement standard ratings used to indicate the level of protection for electrical equipment against solids and liquids.

Myledy is equipped with state of the art manufacturing equipment utilizing cutting edge technology and top quality silicone glue to offer anti-yellowing, resistance to high and low temperature and diverse IP rating lever IP62~IP68 waterproofing for special applications.

IP20

Non-Waterproof

IP62

Silicon Glue

IP65

Silicon Sleeve

IP66

Silicon Extrusion

IP67

Silicon Glue with

Half Sleeve

IP68

Silicon Glue With

Full Sleeve

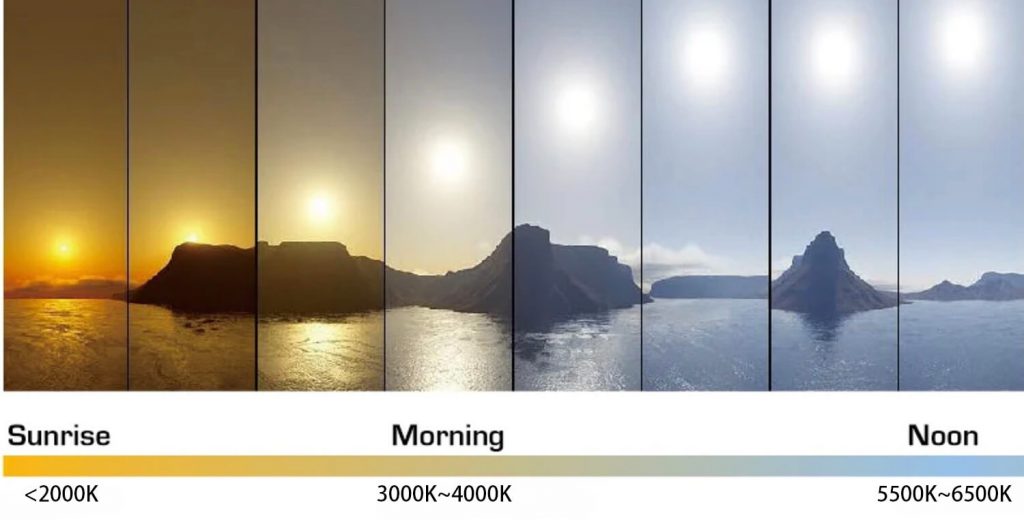

CCT Spectrum Reference:

What Is CCT?

CCT(Correlated Color Temperature at which the light works) is represented by the number and the capital letter K (Kelvin), tells you the hue of white light. The smaller the Kelvin rating, the warmer the light, and vice versa. “Warm” and “Cool” do not describe the working temperature of the light, but rather the effect of light on us.

What CCT Should I Choose?

The color temperature of the LED lighting effects your mood. The amount of white in your room will magnify this effect. If your space has white walls and ceilings, and you choose a warmer white tone, it will look warmer than using a dark color scheme. Conversely, if your room is dim, you may need a cooler white tone so you can see the room clearly.

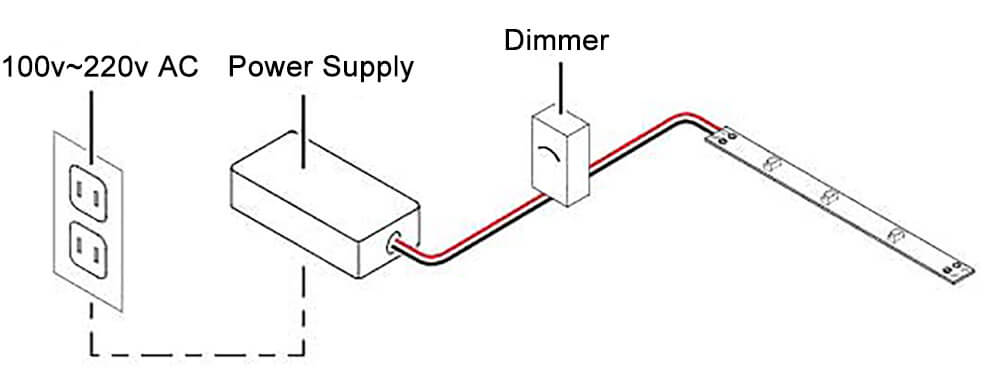

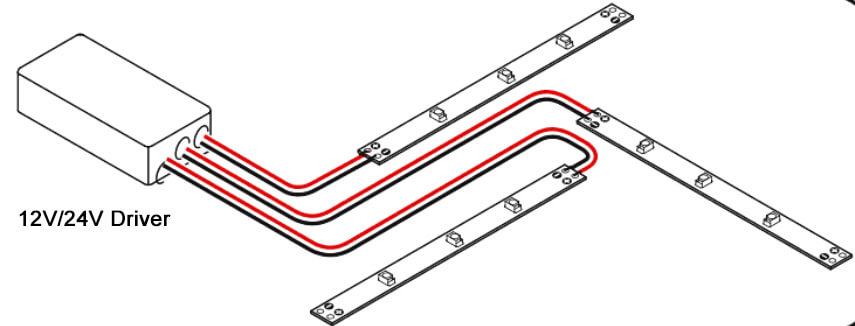

Wiring Diagram:

First, Calculate The Wattage of Each LED Strip — You should already have an idea of how much power will be required to run your LED light tapes. However, there might be some additions or subtractions in the number after you’ve cut and connected the tapes together. So, calculate the overall wattage required to power your flexible LED light strips again.

Second, Find Compatible Power Supply — You need to choose a driver that will use only 80% of its overall power to run the LED tapes. This is very important for the longevity of both your power supply and LED strips.

Third, Connect LED Strip to Power Supply — You can make series circuit or parallel circuit for the LED strip lights. And all Myledy LED strip lights are dimmable, you can also connect a dimmer for better brightness control.