Special Article

- Bendable

- side emitting

- high density

- super long

- multi-row PCB

- Ultra narrow

- spotless lighting

More Advantages of IP62 Silicone Glue LED Tape Connectors:

Hippo ND Series – IP62 silicone glue LED strip connectors are an excellent and reliable way of joining LED strip to strip or strip to cable.

Simply select the correct size of connector, insert the tape and close the connector until it latches. This will make a strong physical and electrical connection ensuring a reliable joint.

| Item No. | LD-ND0802 | LD-ND0812 |

| Joint type | strip to strip joint | strip to wire joing |

| Wire Length | No wire | |

| Pin pitch | 3.6mm | |

| Working voltage | DC3V~24V | |

| Rated current | 5A | |

| Workable wire Gauge | 22 -18 AWG | |

| Wire Color | Red & Black | |

| Item No. | LD-ND1002 | LD-ND1012 |

| Joint type | strip to strip joint | strip to wire joing |

| Wire Length | No wire | |

| Pin pitch | 5mm | |

| Working voltage | DC3V~24V | |

| Rated current | 5A | |

| Workable wire Gauge | 22 -18 AWG | |

| Wire Color | Red & Black | |

| Item No. | LD-ND1004 | LD-ND1014 |

| Joint type | strip to strip joint | strip to wire joing |

| Wire Length | No wire | |

| Pin pitch | 2.5mm | |

| Working voltage | DC3V~24V | |

| Rated current | 5A | |

| Workable wire Gauge | 22 -18 AWG | |

| Wire Color | Red & Black | |

IP is an acronym “Ingress Protection”, a measurement standard ratings used to indicate the level of protection for electrical equipment against solids and liquids.

Myledy is equipped with state of the art manufacturing equipment utilizing cutting edge technology and top quality silicone glue to offer anti-yellowing, resistance to high and low temperature and diverse IP rating lever IP62~IP68 waterproofing for special applications.

First, Calculate The Wattage of Each LED Strip — You should already have an idea of how much power will be required to run your LED light tapes. However, there might be some additions or subtractions in the number after you’ve cut and connected the tapes together. So, calculate the overall wattage required to power your flexible LED light strips again.

Second, Find Compatible Power Supply — You need to choose a driver that will use only 80% of its overall power to run the LED tapes. This is very important for the longevity of both your power supply and LED strips.

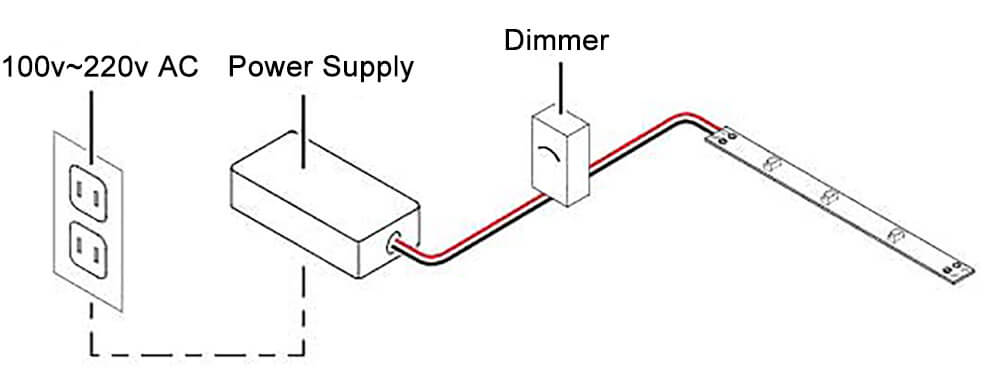

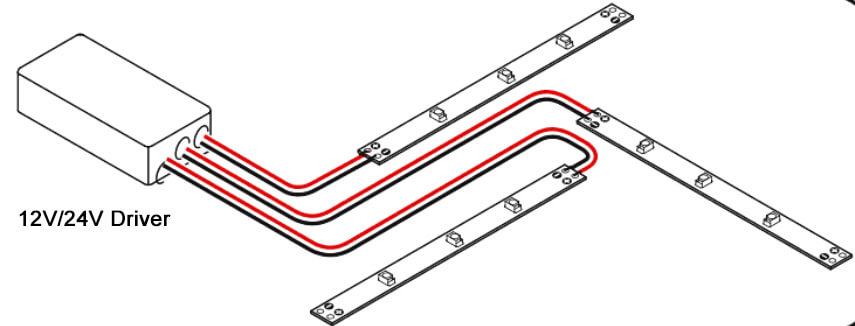

Third, Connect LED Strip to Power Supply — You can make series circuit or parallel circuit for the LED strip lights. And all Myledy LED strip lights are dimmable, you can also connect a dimmer for better brightness control.